Product

Contact Us

3/8" Tractor Bucket Grab Hooks with 1/2" Tie Down Ring and 2" Receiver Grade 70 Grade Forged Steel Bolt-On Grab Hook for John Deere Compact Tractor Bucket RV UTV Truck Max 4700LBS

- Commodity name: 3/8" Tractor Bucket Grab Hooks with 1/2" Tie Down Ring and 2" Receiver Grade 70 Grade Forged Steel Bolt-On Grab Hook for John Deere Compact Tractor Bucket RV UTV Truck Max 4700LBS

Key words:

Product Description

Tractor Bolt is designed for a perfect fit on top of your John Deere tractor bucket. The support adopts 1/4" heavy duty steel plate foundation, which greatly improves the strength of the central part of the bucket. Tractor Bolt includes 2* 5/16” forged grab hooks (G70) rated at 4700lbs Working Load Limit (Accepts 3/8” chain and under),2* 1/2” forged D rings 4000lbs Working Load Limit, 1* 2” receiver with 5/8” center hole. All parts are MIG welded on a 1/4" thick steel plate. Strong gloss powder coated finish. Even if it is used outdoors for a long time, it will not rust. Every Mount Includes 6* 7/16” Grade 8 bolts (1.5” length) and lock Nut. Please confirm the position of the mounting hole before installation, if necessary, please pre-drilling the hole where the bolt needs to be installed. The universal tractor bucket hooks was designed to work on many buckets of different sizes and shapes. Great for John Deere, Kubota, Mahindra, Kioti, New Holland. Checking dimensions (the top portion of bucket has to be 4- 3/8” wide or wider for proper mounting) to see if it will fit your bucket where you would like to mount it! Also make sure the underneath side of your bucket has room and access to drill the holes and attach all hardware.

Parameter Table

| Item | Dimensions (in.) | Weight Each (kg) | Finish | ||||||

| A | B | C | D | E | F | G | |||

| JCT131-006 | 22 | 5 | 3 | 2.4 | 2.25 | 2.36 | 2.36 | 6.9 | Zinc-plated, Chrome,Powder Coated or Customized |

| JCT131-007 | 21-1/2 | 4-3/8 | 2.52 | 2.4 | 2.25 | 2.36 | 2.36 | 6.5 | Zinc-plated, Chrome,Powder Coated or Customized |

Procution Process

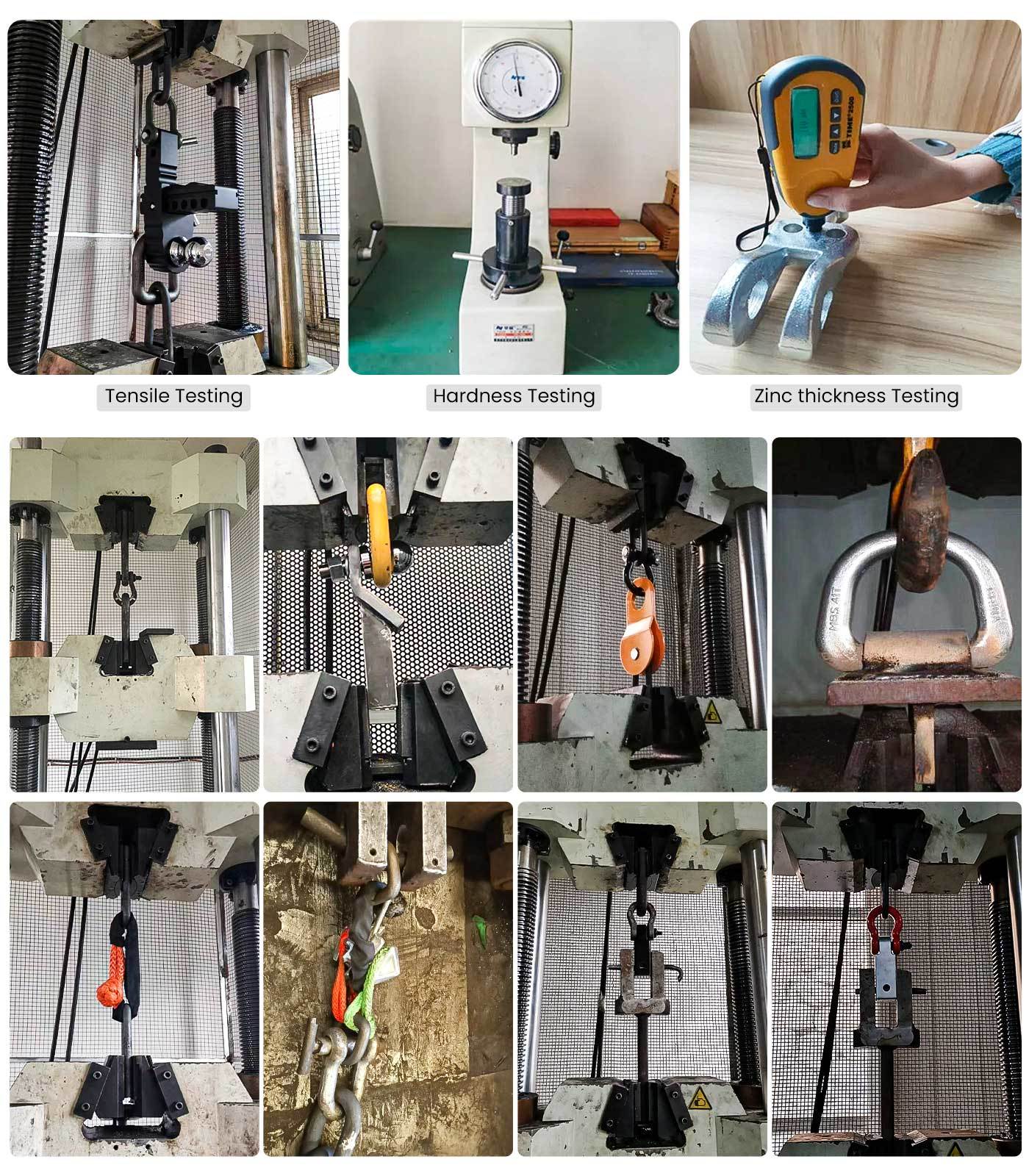

Quality Control

From Material to the end produce process, every step must in accordance with ISO9001 standard.

The tests including Dimensional test, Zinc thickness test, Tensile test and Hardness test.

Testing Machinery

| Machine Name | Brand & Model No. | Quantity | Number of Year(s) Used | Condition |

| lmpact Tester | No Information | 1 | 3 | Acceptable |

| Rigging Tester | No Information | 1 | 5 | Acceptable |

| Universal Tester | No Information | 5 | 3 | Acceptable |

| Failure Tester | No Information | 2 | 5 | Acceptable |

| Hardness Tester | No Information | 2 | 2 | Acceptable |

| Spectrometer | No Information | 1 | 2 | Acceptable |

Packaging & Shipping

Evaluate

JINGCHENG Advantages

Provide OEM/ODM sevice, Thinkwell can according to your idea or a sketch to provide free design.

Strict quality control based on ISO9001 and 12 months warranty.

Enough stock for standard items / 7~10 days ready date for under 1000pcs q’ty, Low MOQ, moer than 10pcs is accepted.

FAQ

01

Are you factory or Trading Company?

02

What is your company advantages?

03

How do you control your quality?

04

What's your company mainly exporting market?

More Products

More Products