Product

Contact Us

Recovery Traction Boards, Offroad Tracks Board, Traction Tire Ladder, 4WD Traction Mats for Sand, Mud & Snow

- Commodity name: Recovery Traction Boards, Offroad Tracks Board, Traction Tire Ladder, 4WD Traction Mats for Sand, Mud & Snow

Key words:

Product Description

Designed with unique jack base in the center of the traction board is for emergency work, compatible with offroad jack.And a bunker recovery boards could be placed under it to provide a solid surface for lifting. he interlocked diamond array aims to offer stronger flexibility,off road traction board can be bent to up to 120° without fracture.These recovery tracks (weighed 5.92kg per pair) can even withstand weight of up to 10 tons. Our traction mat is made of upgraded automotive grade polypropylene, flexible, lightweight, durable, easy to clean.Take into consideration the extreme temperature user will encounter in the wild, are able to work all year round between temperatures from -30°C (-22° F) to 60°C (140° F). Abandoning traditional design, both sides of the traction recovery board adopt the same diamond array construction to significantly increase friction and can also be used to get your vehicle unstuck. The cross-shaped teeth, well positioned to bite the tyres to prevent vehicle from slipping back, will not melt against drastic wheel spin.Sand board bottom with diamond array construction will firmly sink into the ground to provide firmer base for recovery. Contoured to fit most tyres, the sand ramps are designed for an easier entering under the tyre and drive up, and track board can also be used as shovels.Place the traction pads under wheels, and help car to get out of mud, sand, snow. Ergonomic handles add comfort when using its end as a shovel, 10 keyholes allow convenient mounting, and these mud sand snow track can be nested and better stacked to save your precious in-vehicle spaces.

Parameter Table

| Item | Dimensions (in.) | Working Load Limit (kg) | Weight Each (kg) | Finish | ||

| A | B | C | ||||

| JCT130-005 | 10.55 | 40.9 | 2.6 | 10,000 | 3.4 | Zinc-plated, Chrome,Powder Coated or Customized |

| JCT130-006 | 12.9 | 40.4 | 3.07 | 15,000 | 3.5 | Zinc-plated, Chrome,Powder Coated or Customized |

| JCT130-007 | 12.4 | 42.5 | 2.6 | 20,000 | 4.5 | Zinc-plated, Chrome,Powder Coated or Customized |

Procution Process

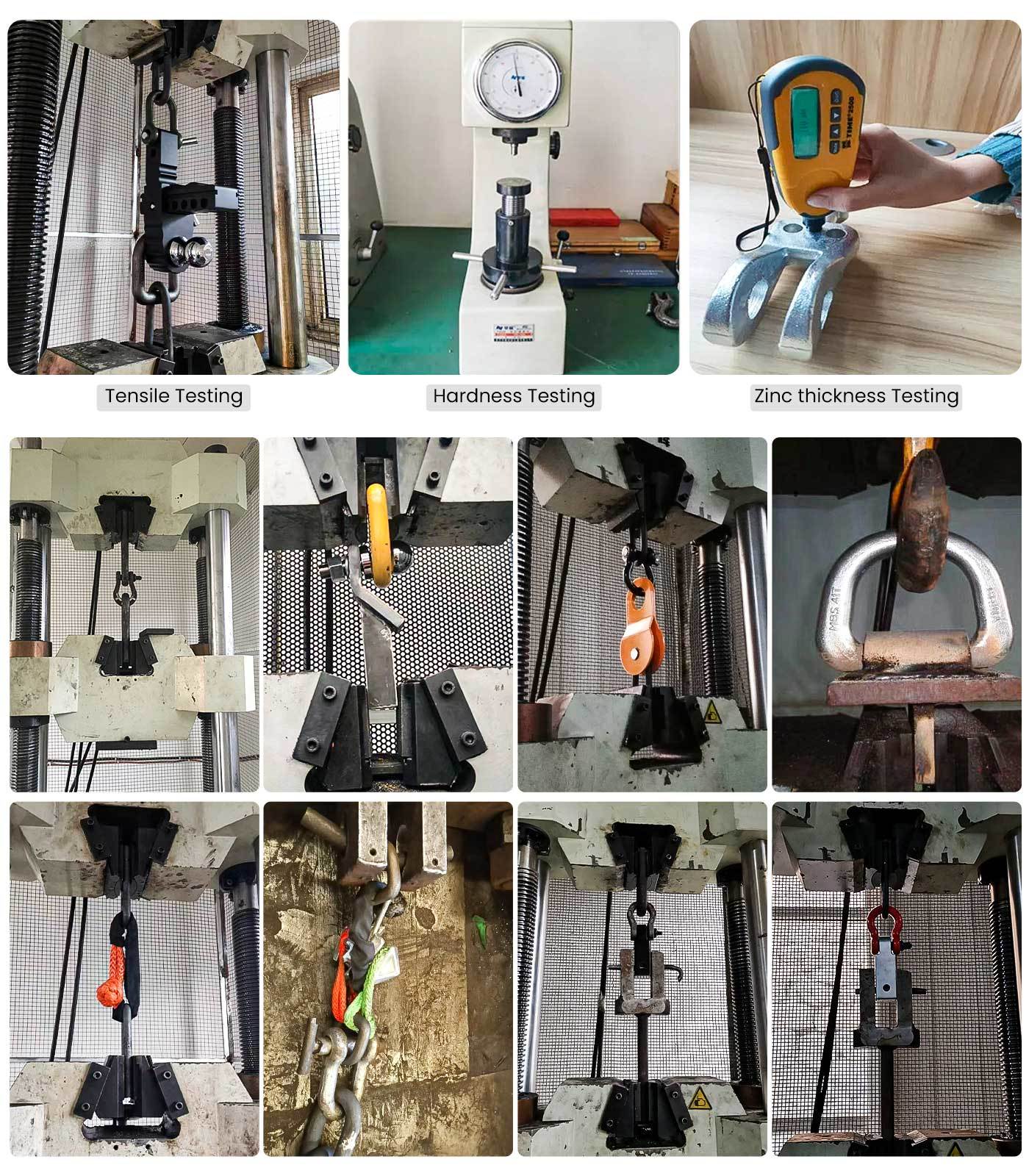

Quality Control

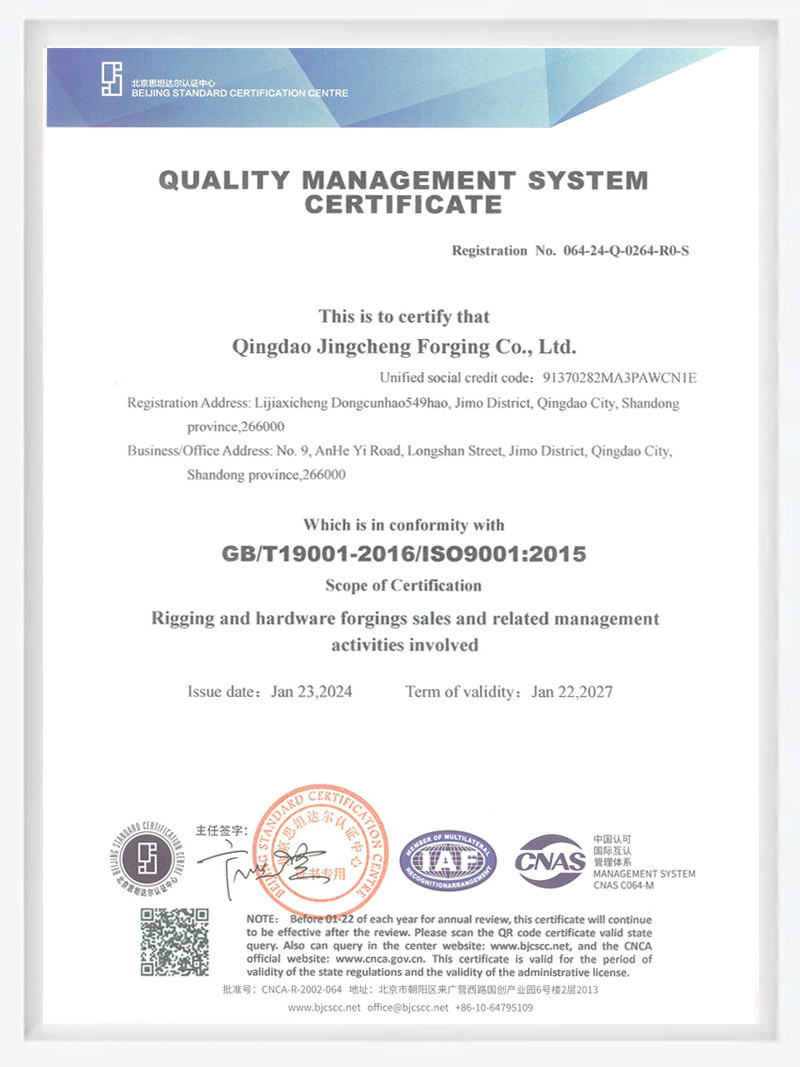

From Material to the end produce process, every step must in accordance with ISO9001 standard.

The tests including Dimensional test, Zinc thickness test, Tensile test and Hardness test.

Testing Machinery

| Machine Name | Brand & Model No. | Quantity | Number of Year(s) Used | Condition |

| lmpact Tester | No Information | 1 | 3 | Acceptable |

| Rigging Tester | No Information | 1 | 5 | Acceptable |

| Universal Tester | No Information | 5 | 3 | Acceptable |

| Failure Tester | No Information | 2 | 5 | Acceptable |

| Hardness Tester | No Information | 2 | 2 | Acceptable |

| Spectrometer | No Information | 1 | 2 | Acceptable |

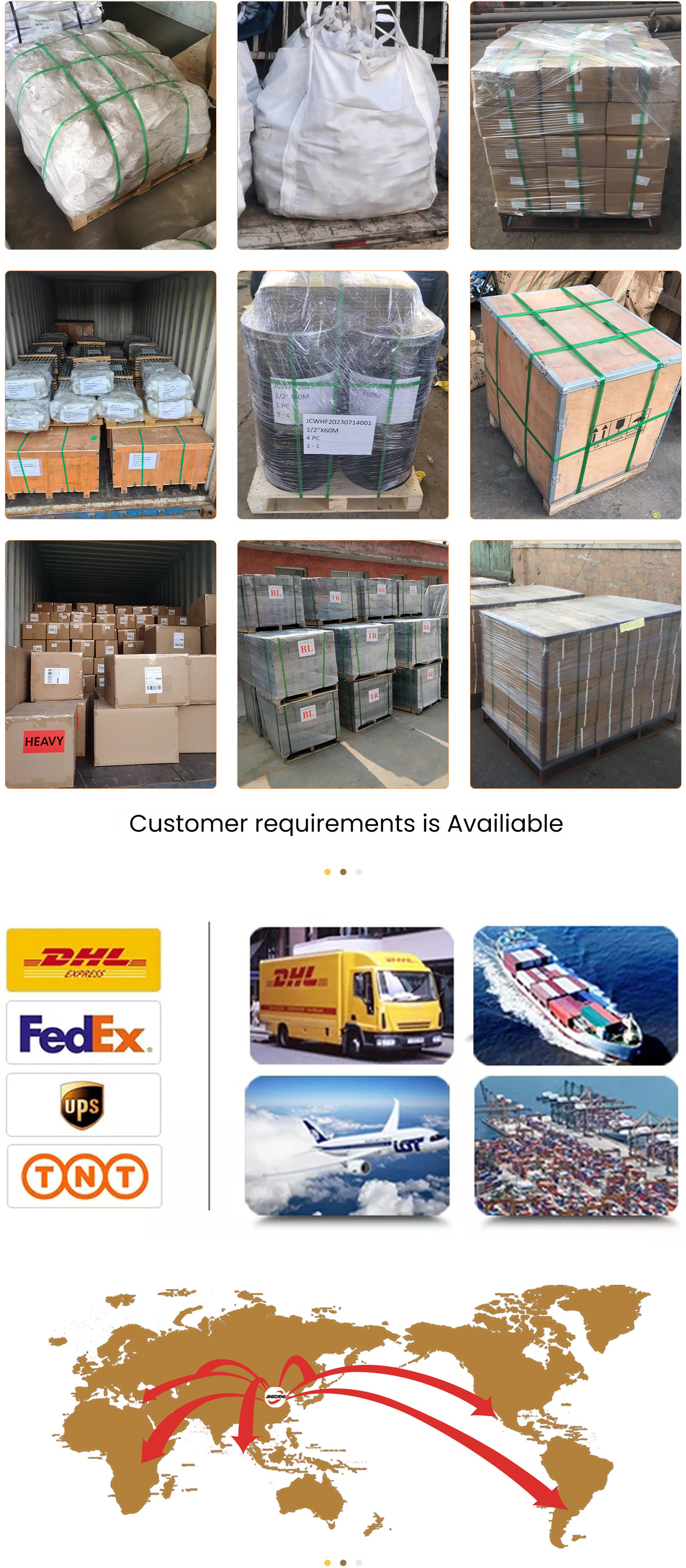

Packaging & Shipping

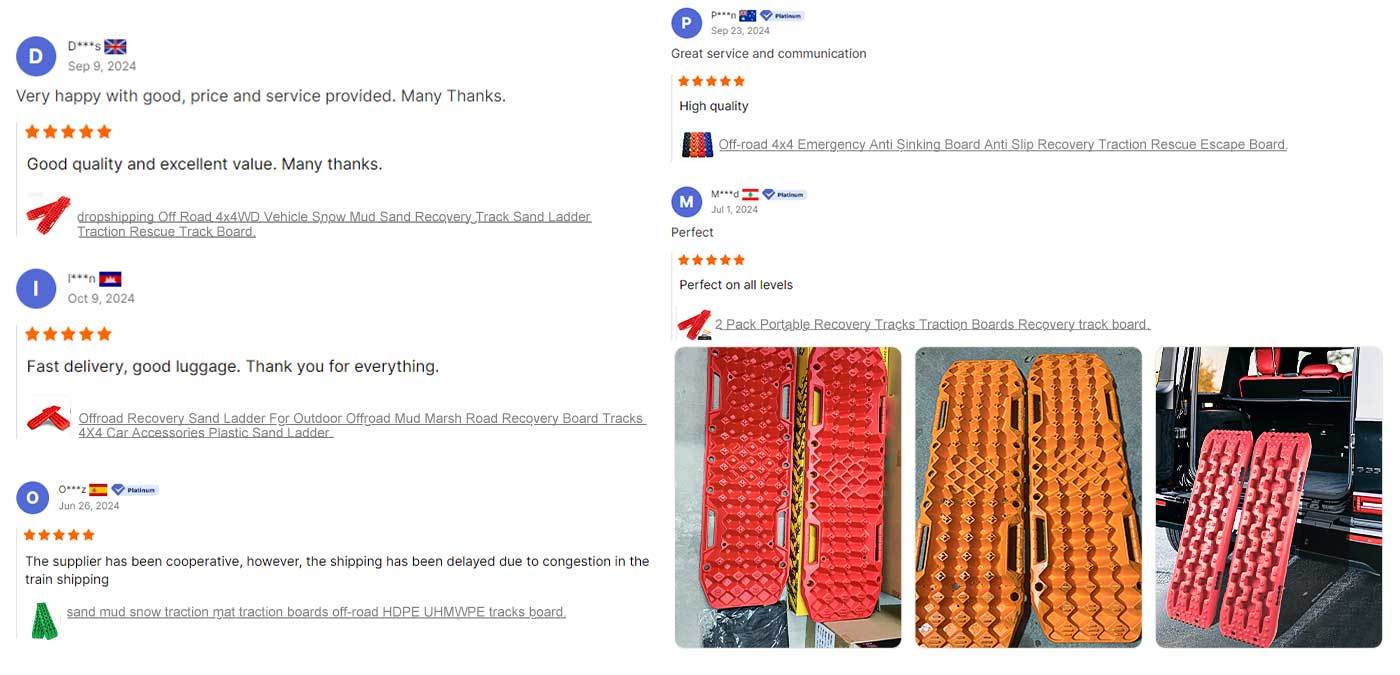

Evaluate

JINGCHENG Advantages

Provide OEM/ODM sevice, Thinkwell can according to your idea or a sketch to provide free design.

Strict quality control based on ISO9001 and 12 months warranty.

Enough stock for standard items / 7~10 days ready date for under 1000pcs q’ty, Low MOQ, moer than 10pcs is accepted.

FAQ

01

Are you factory or Trading Company?

02

What is your company advantages?

03

How do you control your quality?

04

What's your company mainly exporting market?

More Products

More Products